|

|

|

|

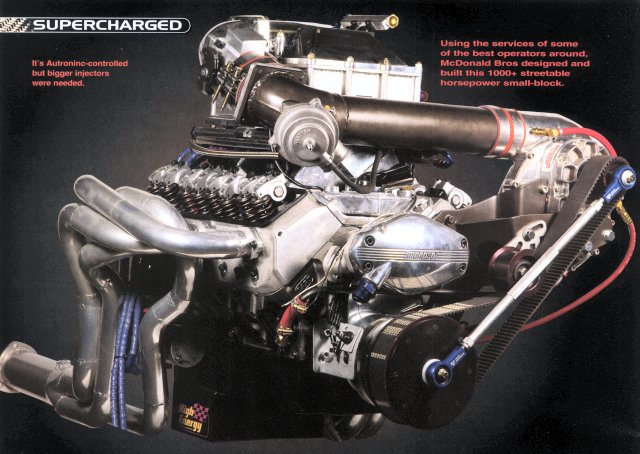

This

Dart-based, Lunati-filled, Racer Pro-topped powerhouse boasts a Vortech

V4Z supercharger and a Mondo air/water aftercooler. All up, when testing

was stopped at 7000rpm (boost had become too high at 30lbs/in2) there was about

1100hp on tap. |

|

|

|

|

Super Camaro, Air/liquid

intercooled beast.

Start small and work your way up doesn't seem to be a concept Michael

understands. You see, this is his first project car ever, and it's not a bad

start. Originally, he had in mind a stroker making around six or seven hundred

horsepower - until he saw a rotary with plates that read "EATAV8" and,

he says, thought, "No, that can't be allowed." It was even more

annoying because the owner had a big mouth and was a mate's mate so he couldn't

get away from him.

That's when he decided 1000hp was going to be the minimum figure for the

project, and a supercharger seemed like a good way of achieving it. Then he

figured, as long as he was going to be spending the sort of money this was all

going to cost, he should have a go at the Horsepower Heroes at the Summernats.

At first, Mike had taken the standard car to McDonald Bros Racing just to get a

decent tune because it was running so badly when he got it. He chose McDonald

Bros because they'd built an 11-second engine for a friend on a budget and it

performed very reliably.

He liked the racing work they did and the reputation they had so he decided to

get them to fit a roll-cage and tubs. He paid his deposit and, as Mike and the

boys at Ray's got talking, things got out of hand. That, along with the factors

just mentioned, was a contributing factor in deciding what the power figure

should be and how to achieve it.

|

|

|

|

|

|

|

|

Far

Left: Copper gaskets and o-rings seal the bores and did a good job despite the

fact that they went 10lbs/in2 over the intended figure.

Left:

The blow-off valve empties the inlet tract when the throttle is shut

abruptly at high revs and high boost levels. We have more about Vortech

Superchargers elsewhere in this issue. |

|

|

|

|

|

|

HOT FAVOURITES

Of course, superchargers heat air so an intercooler was going to be needed. This

was particularly important because of the dyno competition at the Summernats.

Mike noted that the event is always held during extremely hot weather and

conditions around the dyno are usually crowded and even hotter, so an air/air

intercooler didn't seem like the best way to go.

An air/water intercooler, on the other hand, can absorb huge amounts of heat and

seemed like a good idea. He'd been talking to Tony Rullo at C.A.P.A about the

supercharger and Tony suggested a Vortech Mondo air/water intercooler would be

the thing to use, particularly because no one in Australia had fitted one

before.

The mondo looked good because Vortech said it's capable of supporting a 1700hp

setup. As company literature says, some drag race teams don't use a

recirculating fluid circuit incorporating a radiator with the mondo - they

simply run a small supply of iced water through the unit for the very short

duration of the race.

To get things really cool, Michael is currently wondering how you'd go about

using liquid nitrogen as the cooling medium. This, of course, is just an idea at

the moment. It would certainly keep temperatures low, but questions like what

sort of pump to use and other technicalities would have to be solved.

Eventually, Michael wants to fit nitrous oxide.

The project as it stands at the moment has been a collaborative effort. Lee

Kavanagh brought in the Dart 4 block and Lunati stroker kit. Duggans prepared it

and the associated components. Graeme Cerini at Total Performance chose the

Racer Pro heads and ported and prepared them. Crow Cams were advised of the

objectives for the project and supplied an appropriate cam and, of course,

C.A.P.A supplied the supercharger and cooler.

|

|

|

|

|

|

|

|

A Lunati stroker kit gives the cubic displacement needed to take the

output of the V4Z supercharger. |

|

|

|

|

|

|

SHORT DETAILS

Warren Duggan explained that the block arrived with most things,

like align-honing the mains, already done.

However, the bores had to be prepared and, as you'd expect, boring and honing

were carried out with a torque plate attached. There are no real surprises in

any of this and clearances were set to usual specs of around 0.0025"

through the mains and rods. Piston-to-bore clearances were set to kit

recommendations plus about another 0.001" to accommodate the expansion the

extra heat was likely to create.

Compression is about 8:1 and, because the pistons had to have such a large dish

to accommodate it, Warren was worried that at 0.200" the crowns were going

to be too thin for the operating conditions. As a precaution, the combustion

faces were ceramic coated by Competition Coatings to help keep the heat out and

prevent the crown going soft and collapsing. As it turned out, Warren's concerns

were justified - almost. More on that in a minute.

Copper gaskets are another aspect to handling the heat involved. Although some

people don't have that much luck with them, Warren says they work fine if used

correctly. Using the right sealant is essential, but just as important is the

amount applied. It's definitely a matter of more is worse. Just a light coating

of ThreeBond white silicon around the holes on either side of the gasket is all

that's needed.

An o-ringed block is the other requirement for getting them to work at their

best in this sort of application. However, it's essential to have the o-rings

sitting above the deck by the correct amount or this technique doesn't work

effectively either. Warren says about 0.010" protrusion works best.

Nothing much else out of the ordinary was done except that the combination of

block, heads, cam and rockers called for a bit of die-grinder modification to

the pushrod holes in the heads, but things like that are expected in a highly

customised setup like this.

The rods needed a bit of attention because the cut-outs in the big-ends weren't

quite deep enough for the bearings to seat properly. This would make it

impossible to obtain an accurate measurement across the bearing and could cause

failure due to inadequate heat transfer.

Problems like this pop up from time to time but that's what pre-assembly

checking is all about. Warren says that the other day, on another engine, he

found that the notches for the tangs were too narrow. Any sort of quality engine

build should include thorough pre-assembly as part of the process to catch

things like this before everything gets tightened up.

|

|

|

|

|

|

|

|

A custom manifold had to be fabricated to take the

aftercooler. The Mondo Cooler features a triple-core, double pass system that

can pass up to 2500cfm. That's enough for around 1700hp. |

|

|

|

|

|

|

NOT MUCH NEEDED

We also spoke to Graeme Cerini about the heads. He points out

that these 18° Racer Pro units are good straight out of the box and don't need

much work for excellent results.

Inlet port volume is 250cc and a bit of bowl-work and a general clean-up in

combination with widened short-turns on the inlets sees them right. However, in

this application, because of the supercharger, flow through the exhausts was

lifted to about 75-80 per cent of the inlets whereas 65-70 per cent is the usual

figure. Graeme says the preparations described are all that's needed as long as

the cuts for the seats are all of the appropriate size and where they should be.

On that matter, the top-cuts were 30°, the seats 0.050", the 60° cuts

0.100" and a 75° cut blending all that work into the bowl. Valves are

2.150" and 1.625" with Comp Cams springs, titanium retainers and 10°

collets. As just about always, Graeme polished the chambers too (although they

don't shine like the iron units).

Finally, the whole package was assembled and ready to go. Chris from McDonald

Bros says it was all run in and happy about 20 minutes after they got it bolted

in to the dyno. Lovely.

They started mapping the Autronic and things were going well until about 4500rpm

when it started to carry on a bit like it was misfiring. Initially they thought

it electrical, but then looking at the computer screen showed the injectors were

running at 95 per cent and running out of fuel. The top two injectors in the

manifold were set to come in on 100 per cent at about 3000rpm and that got the

whole thing to 5000rpm before it ran out of fuel.

A set of Indy Blue injectors were fitted and it ran straight to 6500 on the

first pull, sounding clean all the way and making about 950lbs/ft and 1090hp.

Once that figure was established it was re-mapped everywhere else.

On the last day they did eight runs and managed 1150hp on the final run at

6800rpm with 30lbs/in2 boost. Earlier, at about 4000rpm, they only had about

12lbs/in2 and thought there wouldn't be enough because they only planned to turn

it 2500rpm faster than that, Chris says that between 4500 and 5500rpm another

13lbs/in2 appeared.

Originally, they'd never intended to go past 20lbs/in2, so the intention is to

fit a smaller pulley (on the crank) to slow the supercharger down a bit. This

will allow them to rev the engine harder for a higher top-end figure while

maintaining a sensible pressure ratio (see our turbocharger article), although

the supercharger is rated to 35lbs/in2.

The high boost was all a bit stressful on the various components and Warren

Duggan's concern about piston crown thickness was justified. Chris says that

when they pulled it down, the areas around the fly-cuts for the valves showed

signs of starting to soften. The gasket was also starting to show signs of

movement in a couple of places. On the other hand, the bearings looked brand

new, like the engine hadn't been started.

|

|

|

|

|

|

|

|

Far

Left: Before...

Left: ...after. It took a reasonable amount of wriggling but it went

in quite easily. There'd certainly have been some tears if

modifications to the tower hadn't been accurate. |

|

|

|

|

|

|

WHEN THE'RE RIGHT THEY'RE RIGHT

We looked at some of Vortech's technical

information relating to the Mondo cooler and they make the point that,

technically speaking, this is really an aftercooler, along with virtually

everything else described as an intercooler in automotive applications.

An intercooler, they point out, is a heat exchanger positioned between two

compressors in a two-stage pressurised setup. I hate it when I find out things

like that. The world isn't going to change and now, every time I yield to

popularism and write intercooler, I'm going to twitch.

In any case, the a-f-t-e-r-c-o-o-l-e-r worked well and inlet temperature stayed

around 30-35°C until they gave it a serve and temperatures jumped up to about

45° at 7000rpm.

Apart from the tremendous amount of heat an air/water aftercooler can absorb,

the other advantage is that these units can be positioned right at the engine

because they don't rely (directly) on airflow to remove the accumulated heat.

This results in reduced flow loss compared to that seen in some air/air

applications with convoluted ducting. Vortech summarises the advantage by

stating that their air/water aftercoolers take the "cool to the inlet

charge" rather than the "inlet charge to the cool". Sounds cool

to us.

Story and Photos by Paul Tuzson

|